At Kingfisher Packaging, we know that efficiency is everything in today’s manufacturing, engineering, and metals industries. Businesses continually invest in advanced machinery to boost productivity, cut costs, and reduce their carbon footprint. But one crucial area is often overlooked: packaging efficiency. Poor packaging slows down operations, increases labour costs, and can lead to costly product damage in transit.

At Kingfisher Packaging, we know that efficiency is everything in today’s manufacturing, engineering, and metals industries. Businesses continually invest in advanced machinery to boost productivity, cut costs, and reduce their carbon footprint. But one crucial area is often overlooked: packaging efficiency. Poor packaging slows down operations, increases labour costs, and can lead to costly product damage in transit.

That’s where Kingfisher Packaging’s innovative packaging solutions make the difference. At the recent UK Metals Expo 2024, we showcased how our packaging machines and sustainable materials help manufacturers, fabricators, and metal processors save time, reduce costs, and improve overall efficiency.

Packaging Machines Designed for the Metals Industry

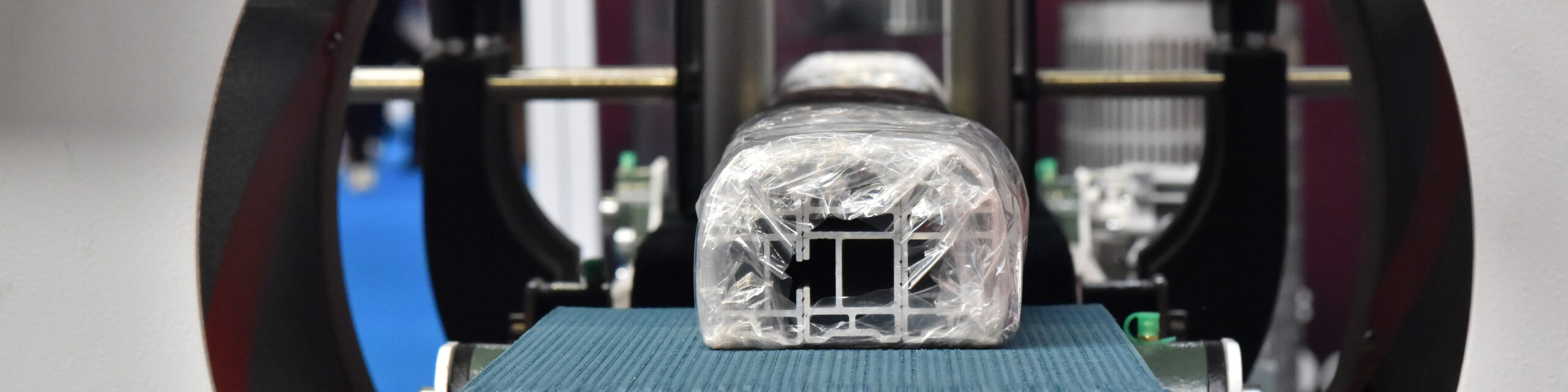

Our Omegatech® and Wrapsolut wrapping machines were a highlight of the expo. Built to handle the demands of the metals sector, these machines are ideal for packaging:

-

Sheet materials

-

Profiles and extrusions

-

Pipes, rods, and coils

-

Fabrications and roll-formed products

Available in semi-automatic, fully automatic, and bespoke designs, these industrial packaging machines deliver:

-

Faster packing speeds for high-output operations

-

Reduced labour costs by automating repetitive tasks

-

Consistent and secure wrapping to minimise damage in transit

-

Lower material use, cutting costs and waste

For metals businesses, this means packaging becomes an efficiency driver, not a bottleneck.

Sustainable Packaging Solutions for Manufacturing and Engineering

Sustainability is central to modern operations, and Kingfisher Packaging helps metals manufacturers reduce their environmental footprint. At UK Metals Expo, we showcased:

-

100% recyclable and biodegradable packaging consumables

-

Autoknot® string-tying machines – a sustainable, efficient alternative to plastic strapping

These solutions allow manufacturers to meet sustainability targets while saving money and improving throughput.

Free Packaging Process Consultancy

Many businesses don’t realise how much they can save until they analyse their packaging. That’s why Kingfisher Packaging offers a free consultancy programme to identify opportunities to:

-

Reduce packaging costs

-

Improve productivity and speed

-

Lower waste and carbon footprint

-

Optimise use of labour and materials

As George Martin, Director at Kingfisher Packaging, explains:

“Many manufacturers aren’t aware of how much their packaging setup could be improved until we partner with them to offer tailored recommendations. It’s rewarding to see the difference that can make in terms of both efficiency and cost savings.”

Why Metals Manufacturers Choose Kingfisher Packaging

Whether you are a large-scale metal fabricator, a manufacturer of extrusions and profiles, or a supplier of pipes and coils, Kingfisher Packaging provides tailored solutions to:

-

Save time on packaging

-

Cut overall costs

-

Protect products in transit

-

Support sustainability goals

From ready-to-ship packaging machines to custom-built systems, we help metals and engineering businesses package more efficiently, more reliably, and more sustainably.

Take the Next Step

Want to see the difference for yourself? Send your products to our showroom and we’ll demonstrate exactly how Kingfisher Packaging can optimise your packaging process.

📞 +44 (0)1823 653400

📧 sales@kingfisherpackaging.com

🌐 www.kingfisherpackaging.com

Innovative Packaging Solutions for the Metals, Manufacturing, and Engineering Industries.